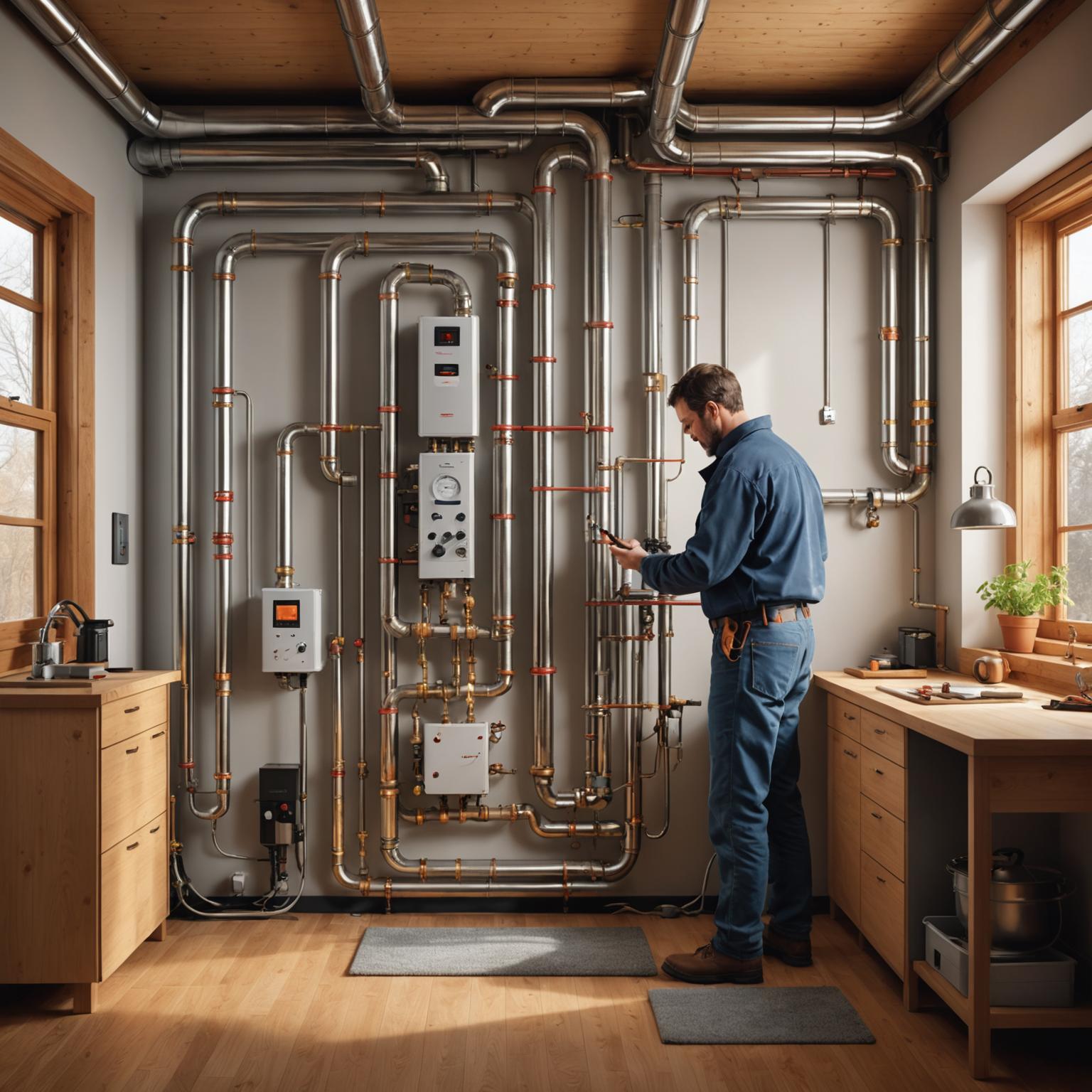

The modern industrial landscape relies heavily on the precise application of heat, where the humble Heating pipe plays a fundamental role in processes ranging from metalworking to fluid transport. As technology evolves, so do the methods for applying this heat. Advanced systems, particularly those utilizing induction heating, are revolutionizing how industries approach tasks like forging, annealing, and bending. These sophisticated techniques offer unparalleled control and efficiency, moving far beyond traditional flame-based methods and setting new standards for quality and performance in manufacturing and fabrication.

At the core of many industrial heating systems are steel heating pipes. Chosen for their exceptional durability, high thermal conductivity, and resistance to extreme temperatures and pressures, steel is the material of choice for demanding environments. These pipes form the backbone of systems that transport superheated fluids or act as conduits within larger heating apparatuses. In the context of induction heating, while the workpiece itself is often the target, the surrounding infrastructure, including any piping, must be robust enough to withstand the intense thermal environment. The selection of the right grade and specification of steel heating pipes is a critical first step in designing a reliable and long-lasting industrial heating solution, ensuring structural integrity even under repeated thermal cycling.

Achieving maximum heating pipe heating efficiency is a primary goal in any industrial application, as it directly impacts operational costs and product quality. Traditional heating methods often suffer from significant energy loss to the surrounding environment. Induction heating technology, as exemplified by systems like the HT-250801 induction coil, addresses this challenge directly. By generating an electromagnetic field, it induces an electrical current within the metallic workpiece itself, heating it rapidly from the inside out. This process is incredibly targeted, concentrating the energy precisely where it's needed. The result is a dramatic improvement in heating pipe heating efficiency, with faster heating times, uniform temperature distribution, and minimal wasted energy, which is crucial for maintaining the metallurgical properties of high-performance components.

A complete heating system is more than just its primary heating element; it relies on a suite of specialized heating pipe accessories to function safely and effectively. These components can range from temperature sensors and control units to the applicators themselves. For instance, tools like the HT-250801 Torch Heat Inductor and its associated induction coils are sophisticated accessories designed for precision. The ergonomic design, temperature-resistant materials, and engineered nozzles of such tools provide operators with complete control over the heat application. This level of precision is essential for complex tasks that require meticulous attention to detail, ensuring that processes like shaping and hardening are performed consistently and safely. The right heating pipe accessories are not just add-ons; they are integral to harnessing the full power of modern heating technology.

Proper system design is paramount for success, which is why a comprehensive heating pipe sizing guide is an invaluable resource. This applies not just to the pipes carrying fluids but also to the selection of induction heating components. The geometry, size, and shape of an induction coil must be carefully matched to the workpiece. An improperly sized coil can lead to uneven heating, hot spots, or inefficient energy transfer, compromising the final product's quality. A detailed heating pipe sizing guide helps engineers and technicians select the optimal coil configuration, ensuring that the electromagnetic field is focused correctly for uniform and rapid heating. This meticulous approach to sizing guarantees that the system operates at peak performance, delivering consistent and reliable results for any given metalworking task.

Understanding Steel Heating Pipes

At the core of many industrial heating systems are steel heating pipes. Chosen for their exceptional durability, high thermal conductivity, and resistance to extreme temperatures and pressures, steel is the material of choice for demanding environments. These pipes form the backbone of systems that transport superheated fluids or act as conduits within larger heating apparatuses. In the context of induction heating, while the workpiece itself is often the target, the surrounding infrastructure, including any piping, must be robust enough to withstand the intense thermal environment. The selection of the right grade and specification of steel heating pipes is a critical first step in designing a reliable and long-lasting industrial heating solution, ensuring structural integrity even under repeated thermal cycling.

Optimizing Heating Pipe Heating Efficiency

Achieving maximum heating pipe heating efficiency is a primary goal in any industrial application, as it directly impacts operational costs and product quality. Traditional heating methods often suffer from significant energy loss to the surrounding environment. Induction heating technology, as exemplified by systems like the HT-250801 induction coil, addresses this challenge directly. By generating an electromagnetic field, it induces an electrical current within the metallic workpiece itself, heating it rapidly from the inside out. This process is incredibly targeted, concentrating the energy precisely where it's needed. The result is a dramatic improvement in heating pipe heating efficiency, with faster heating times, uniform temperature distribution, and minimal wasted energy, which is crucial for maintaining the metallurgical properties of high-performance components.

The Role of Advanced Heating Pipe Accessories

A complete heating system is more than just its primary heating element; it relies on a suite of specialized heating pipe accessories to function safely and effectively. These components can range from temperature sensors and control units to the applicators themselves. For instance, tools like the HT-250801 Torch Heat Inductor and its associated induction coils are sophisticated accessories designed for precision. The ergonomic design, temperature-resistant materials, and engineered nozzles of such tools provide operators with complete control over the heat application. This level of precision is essential for complex tasks that require meticulous attention to detail, ensuring that processes like shaping and hardening are performed consistently and safely. The right heating pipe accessories are not just add-ons; they are integral to harnessing the full power of modern heating technology.

The Importance of a Heating Pipe Sizing Guide

Proper system design is paramount for success, which is why a comprehensive heating pipe sizing guide is an invaluable resource. This applies not just to the pipes carrying fluids but also to the selection of induction heating components. The geometry, size, and shape of an induction coil must be carefully matched to the workpiece. An improperly sized coil can lead to uneven heating, hot spots, or inefficient energy transfer, compromising the final product's quality. A detailed heating pipe sizing guide helps engineers and technicians select the optimal coil configuration, ensuring that the electromagnetic field is focused correctly for uniform and rapid heating. This meticulous approach to sizing guarantees that the system operates at peak performance, delivering consistent and reliable results for any given metalworking task.