In our modern world, the invisible forces of heat and energy power countless aspects of our daily lives, from a warm morning shower to a perfectly cooked meal. At the heart of these modern conveniences often lies a meticulously engineered component: the Electrical Coil Tubular. This remarkable piece of technology is a true unsung hero, quietly and efficiently converting electrical energy into thermal energy. Its design and function are fundamental to a vast array of heating systems, making it a cornerstone of both residential comfort and industrial processes. Understanding its role is key to appreciating the innovation that drives our world forward.

The Core of Modern Heating: Tubular Electrical Coils

At its essence, the concept is simple yet brilliant. Tubular electrical coils are specialized conductors housed within a protective metal sheath, often made from premium-grade materials like stainless steel. The design can vary, from sleek U-shaped configurations in immersion heaters to elegant circular patterns in electric stovetops. This outer sheath insulates the inner heating element from the external environment while facilitating optimal heat transfer. As electricity flows through the inner coil, resistance generates heat, which is then efficiently radiated outwards. This process is engineered for maximum performance, ensuring rapid and uniform heating for any application.

Versatility in Coil Tubing Electrical Applications

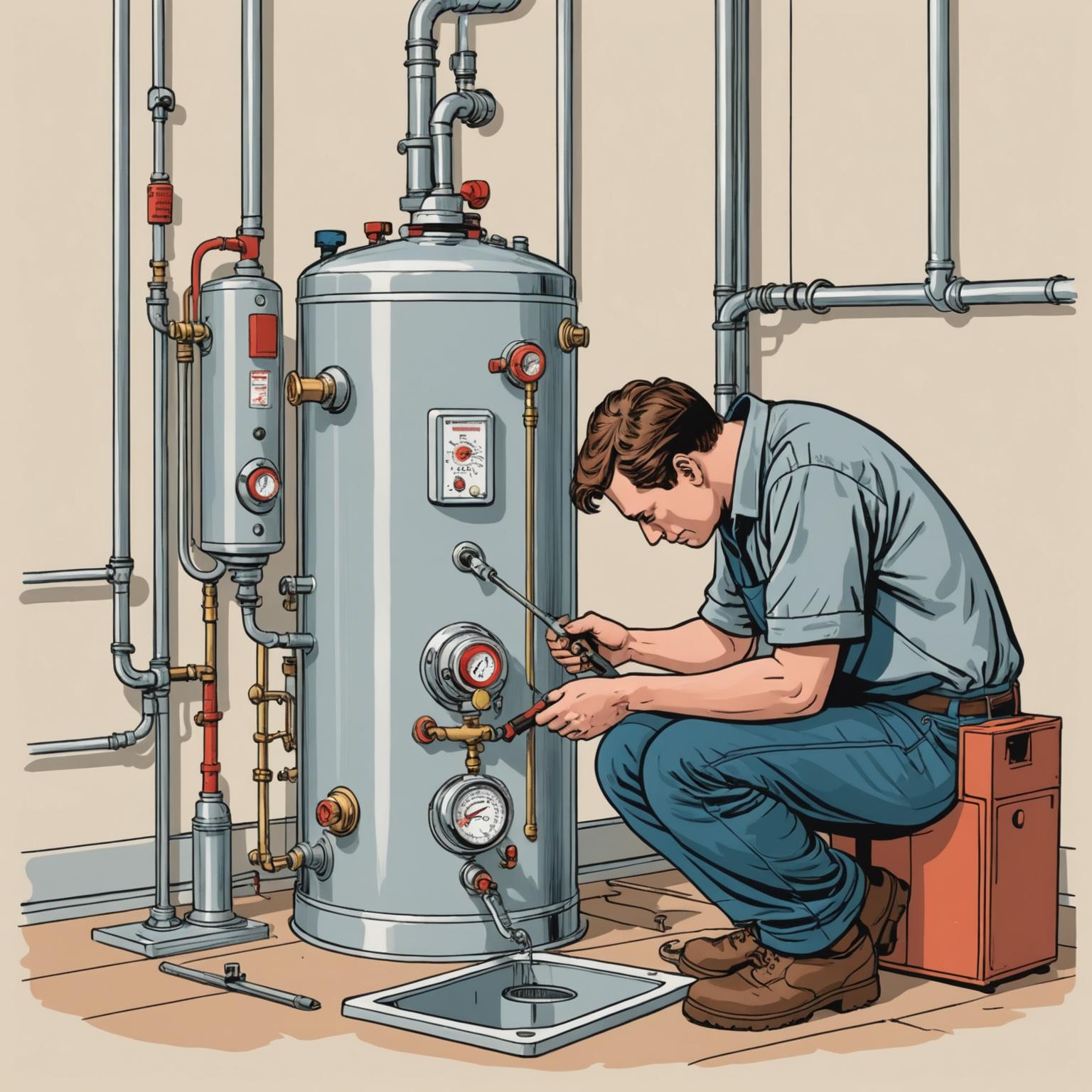

The true strength of these components lies in their incredible versatility. The range of coil tubing electrical applications is expansive, touching numerous industries and consumer products. In a residential setting, they are the power behind immersion water heaters, ensuring a consistent supply of hot water for homes. In the culinary world, they provide the precise and responsive heat for electric stoves, allowing chefs and home cooks alike to master everything from a gentle simmer to a rapid boil. On a larger scale, industrial electrical coils are indispensable in manufacturing processes, chemical heating, and large-scale water treatment facilities, where reliable and powerful heating is a critical operational requirement.

Exploring Tubular Coil Advantages

There are numerous tubular coil advantages that make them a preferred choice for engineers and product designers. Chief among these is efficiency. By design, they maximize the surface area exposed to the substance being heated, leading to faster performance and reduced energy consumption. This translates directly into lower utility bills and a smaller environmental footprint. Durability is another key benefit; constructed from robust materials, these coils are built to withstand high temperatures and harsh conditions, ensuring long-lasting and reliable service. Furthermore, safety is paramount, with designs that minimize risks of overheating and leaks, often incorporating advanced sensors for precise temperature regulation.

Meeting Exacting Tubular Coil Specifications

To ensure optimal performance and safety, every application demands specific tubular coil specifications. Factors like wattage, voltage, sheath material, and physical dimensions must be perfectly matched to the system's requirements. At GUANGDONG WEBO TECHNOLOGY Co., LTD, we understand that precision is non-negotiable. With over 500 dedicated employees and a steadfast adherence to ISO 9001 and ISO 14001 management standards, we have the expertise to deliver solutions that meet the most demanding criteria. Our products, certified by VDE, TUV, UL, CE, and ROHS, stand as a testament to our commitment to global quality standards. We provide comprehensive electrical tubing solutions, ensuring that our partners receive components that are not only powerful and efficient but also impeccably safe and reliable for any end-use, from home appliances to complex industrial machinery.